Understanding Shear Wall Design, Construction, and Importance

When designing any structure, two directions of loading must be considered: gravity and lateral loads. Gravity loads account for critical factors such as the weight of the structure, snow loads, live loads due to human occupancy. Incorrectly designing for these can lead to excess deflection in beams and joists, resulting in cracked ceilings, squeaky floors,…

Sean Buchner

March 5, 2025

10 mins read

When designing any structure, two directions of loading must be considered: gravity and lateral loads. Gravity loads account for critical factors such as the weight of the structure, snow loads, live loads due to human occupancy.

Incorrectly designing for these can lead to excess deflection in beams and joists, resulting in cracked ceilings, squeaky floors, or—in extreme cases—failure of the structural member or building collapse.

Lateral loads such as wind load must also be accounted for to ensure a building does not overturn. Designing for lateral loads is especially critical in coastal areas such as Eastern Long Island, where waterfront residential structures can be exposed to extreme lateral pressure at higher wind speeds.

Whether designing a personal residence or a commercial building, loading considerations are a critical technical aspect of any structural engineering project. Let’s dig deeper into one of the main design aspects of Main Lateral Force Resisting Systems (MWFRS), shear walls.

In this article, we will:

- Answer the question: What is a shear wall in construction?

- Examine how they work and pinpoint their critical role in structural integrity, lateral force analysis, and touch on cost and alternatives

- Outline DiLandro Andrews Engineering best practices when it comes to shear wall construction

- Address frequently asked questions along the way

What is a Shear Wall and How Does it Work?

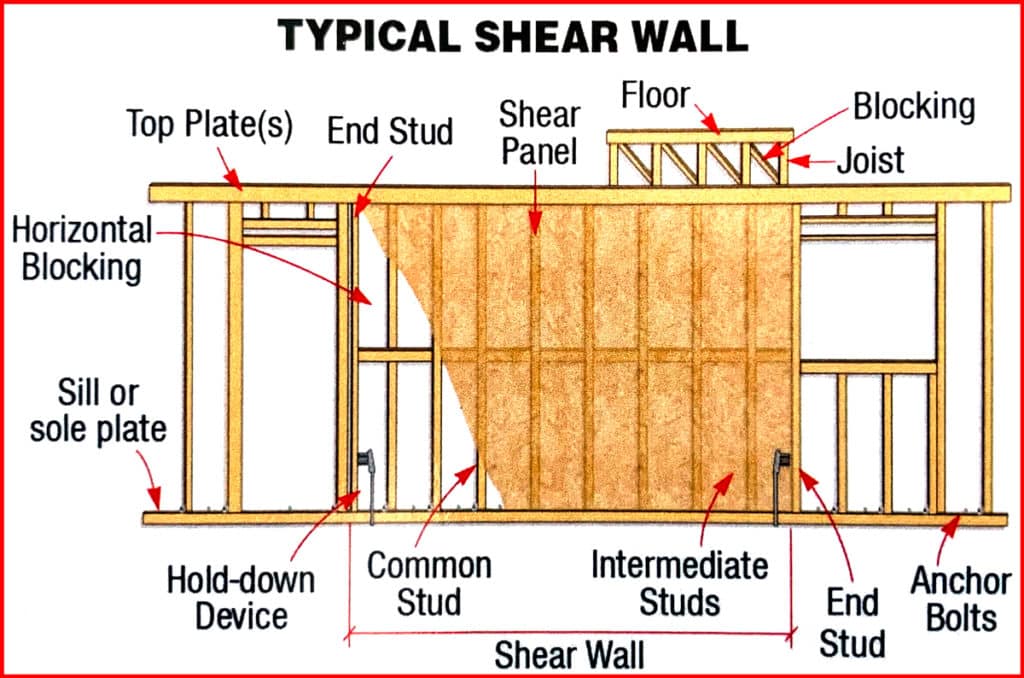

A shear wall is a specialized structural system constructed within buildings to resist lateral forces, such as wind and seismic activity. These vertical elements stabilize the building’s entire framework, distributing the stress brought by external influences throughout the structure. When external forces do apply pressure to a building, shear walls resist the horizontal movement and transmit the load to the foundation.

The structural design of shear walls consists of vertical panels made of reinforced concrete, steel sheets, or wood. As the wall absorbs the forces, it bends slightly but prevents excessive swaying or deformation of the structure. The structural design of shear walls often includes vertical reinforcement (holdowns) to resist uplift forces and prevent a shear wall from overturning, ensuring the wall’s stability and anchoring it to the foundation.

In simpler terms, think of shear walls as rigid panels placed strategically in a structure that absorb the forces pushing against the building, keeping it upright during disruptive events like earthquakes or strong winds.

There are various methods of analyzing exterior and interior shear walls, including empirical design, simplified analysis, and computer modeling. Specific requirements for shear walls vary depending on local building codes and regulations, and consulting with a structural engineer during the design process is critical.

Recommended placement of shear walls in a building depends on factors like building height and shape, floor plan, window/door openings, and overall structural configuration. Depending on the type of building—whether residential, commercial, high rise, etc.—you’ll typically see wood, concrete, or steel plate shear walls used in their construction.

Regardless, both exterior and interior shear walls are typically placed in a structure to provide stability and prevent movement during turbulent conditions.

What Are Different Types of Shear Walls?

Shear walls can be categorized into different types based on their materials, construction methods, and designs:

- Reinforced Concrete Shear Wall: These are the most common type of shear walls and have high strength and stiffness.

- Steel Plate Shear Walls: A more recent kind of shear wall, these provide high strength with less weight.

- Wood Shear Walls: Often used in residential buildings, wood shear walls offer a cost-effective solution.

- Composite Shear Walls: Utilizing a combination of materials, composite shear walls offer improved performance characteristics over traditional absolute material types.

- Dual Systems: In this scenario, both moment-resisting frames and shear walls act together to resist seismic loads.

Why is Shear Wall Design Critical to Structural Integrity?

Shear walls are required in buildings to provide structural stability while resisting lateral forces, reducing the risk of major damage or failure. They are especially important in areas that experience high wind or seismic activity such as coastal regions, as these forces can cause foundation walls of the building to sway and potentially collapse.

How DiLandro Andrews Engineering Designs Shear Wall Systems to Resist Lateral Forces

DiLandro Andrews Engineering specializes in high-end residential construction projects, with a focus on utilizing wood frame and steel construction methods. In addressing the unique challenges presented by these projects, we utilize three primary systems to effectively balance shear force resistance and cost for the core walls.

In order of preference, our firm employs these methodologies: wood frame shear wall construction as per American Wood Council Special Design Provisions for Wind and Seismic (AWC SDPWS), Simpson Strongtie “Strong Walls,” and steel moment frames over openings.

#1: Wood Frame Shear Walls per AWC SDPWS

Wood Frame Shear Walls are the most optimal solution when it comes to both client cost and ease of construction for contractors. This system consists of attaching wood sheathing (plywood) to 2x stud walls—either interior and exterior—and holdowns at end of walls for resisting uplift forces.

The American Wood Council (AWC) outlines strength per linear foot of different shear wall assemblies, varying in size, spacing, and penetration depth of fasteners (nails) for a range of plywood thicknesses. There are two different systems used when design this type of shear wall:

Perforated Shear Wall System

This method designs the shear wall to continuously resist lateral force along the entire length of a wall. It also decreases the strength per foot specified by the AWC in order to account for window and door openings that may be contained within the wall.

The major benefit of this method is decreasing the number of holdowns and reducing tension felt by them, allowing for the use of smaller, less expensive Simpson Strongtie holdowns.

Segmented Shear Wall System

This system requires an engineer to “break up” a wall whenever there is a door, window, or full discontinuity between walls in the same line parallel to wind force. This may allow the engineer to use multiple walls that may not be connected but are in the same—or close to—the same line of action. Both ends of each wall require holdowns, so if a wall is split into two walls due to an opening, there would be 4 total holdowns—rather than just 2 holdowns if the wall was designed as perforated with a reduced strength per foot.

The wood frame shear wall is the simplest and most cost-effective method, but certainly has limitations with walls that have many openings. That’s where we must use two alternative methods to obtain the required strength.

FAQ: What are the different methods of analyzing shear walls?

- Static analysis: Involves evaluating shear wall behavior under static loads using mathematical equations.

- Finite element analysis: Uses computer software to divide the shear wall into small elements and analyze how it responds to various loads.

- Response spectrum analysis: Calculates the response of shear walls in terms of displacements and forces by considering the dynamic characteristics of a structure and earthquake ground motions.

- Pushover analysis: Involves gradually increasing lateral loads on the shear wall until it reaches a predetermined displacement or failure criterion.

#2: Simpson Strong-Wall Shear Walls

One of the limiting attributes of the wood shear wall design is the “aspect ratio requirement.” This is the ratio of the horizontal length of a wall to the height of the wall. As you can imagine a wall that is 30’ tall but only 1’ wide would be incredibly flimsy in a high-wind scenario.

AWC standards require a 3.5/1 aspect ratio for the simple wood shear wall method. If the ceiling height of a wall is 9’, then the minimum length of the common shear wall materials required would be 2.7’. In the situation of designing an exterior shear wall that has 2-4 large glass sliding doors or windows, with only 1’-2.5’ walls in between, those walls can’t be used as per the AWC wood shear wall method.That is why Simpson Strong-Tie engineered a product called Strong-Wall. These are smaller 12”-24” wide products that can be used with heights of 7’-20’. This method can be used in conjunction with wood shear walls when the capacity is slightly lower than the design demand and there are a few unused smaller walls.

FAQ: What is the recommended placement of shear walls in a building?

Shear walls are typically placed in strategic locations within a building to ensure optimal structural stability. Recommended placement of shear walls of course depends on factors like building size and shape, and will always take specific design requirements into account.

Generally it is advisable to position shear walls at the perimeter of a structure or along exterior walls. This allows the effective distribution of horizontal forces and resist lateral loads, such as wind and seismic forces.

Additionally, shear walls should be placed at regular intervals throughout the building to provide consistent support and prevent excessive deformation or movement.

#3: Steel Moment Frames

Steel moment frames are used as a last resort due to project cost. When the engineer is left with a situation where there are not many (if any) wood framed walls—due to a high number of windows and doors—along a line of shear, they are left with no other option than a steel moment frame.

These frames utilize moment connections, either using bolts or welds at the top and bottom flanges of the beam to the supporting columns. The length and height of the frame affects the strength against the imposed lateral force resisting system load. Increasing the beam size helps with the stiffness of the frame, but the biggest factor is the column depth parallel to the lateral force.

Typically, these frames are designed with “pinned” bases to avoid atypical baseplate connections to the foundation. They may also be fixed bases which greatly increase the stiffness of the frame, but this will result in additional detail for the engineer and labor during construction.

FAQ: What is the difference between shear walls and load bearing walls?

Shear walls and load bearing walls serve different functions in a structure. While both provide support, a shear wall resists lateral forces like wind or earthquakes, while a load-bearing wall primarily carries the weight of the structure above it.

The shear wall is designed to transfer these horizontal loads to the foundation and prevent excessive movement or collapse. A load bearing wall distributes the vertical loads from floors and roofs down to the foundation.

DiLandro Andrews Engineering & Shear Wall Expertise

Our skilled structural engineering team has extensive experience designing lateral force resisting systems, specifically when accounting for high-wind in coastal/ocean front projects. Many of the high-end residential projects also require more advanced systems such as Simpson Strong-Walls and steel moment frames.

This is especially true in custom homes featuring modern architectural styles such as narrow shear wall sections accompanied by large glass walls, windows, and doors. We tackled one such architectural challenge in one of our recent projects, Surfside Residence.

The expert team at DiLandro Andrews Engineering brings a wealth of experience solving for and overcoming shear wall challenges to ensure the integrity of any structure, in any element. Get in touch with us today to discuss your engineering service needs and ensure the future success of your project.