Project Details

Architect : A+M+L Architecture

Type : Renovation

Services : Civil Engineering

Surveyor : James Walsh Land Surveyor, PC

Contractor : Ken Rousell, Inc.

Project Summary

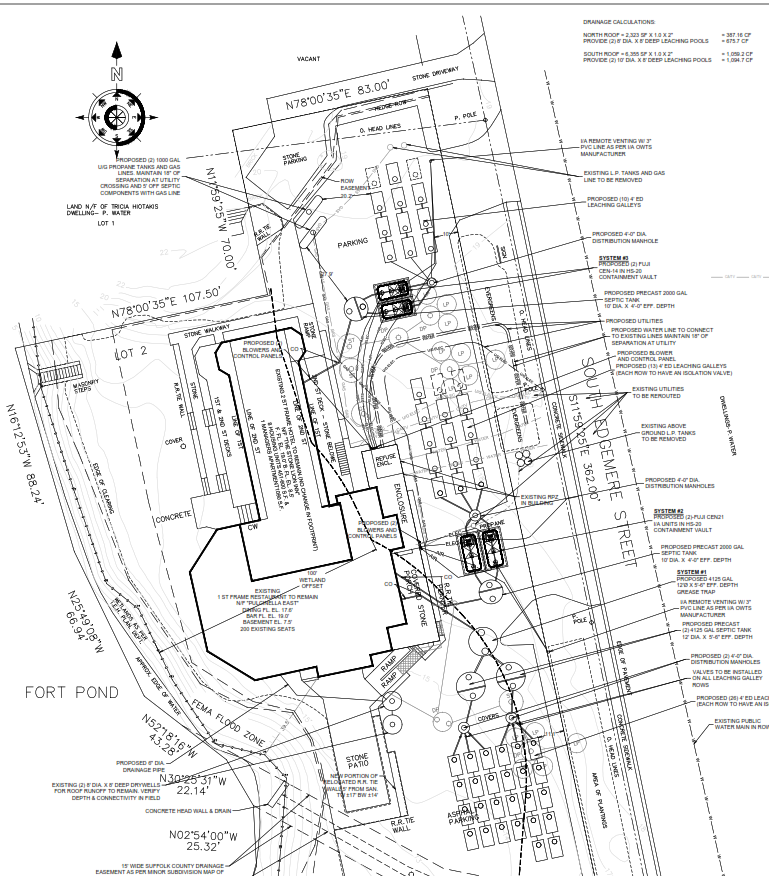

In Montauk, DAE provided the Civil Engineering for an impressive site overlooking Fort Pond. Our civil engineering team designed a cohesive plan to replace the septic systems for a 1.2-acre commercial lot with a restaurant, eight housing units, and an apartment. The property's layout required three separate systems; two for the restaurant (kitchen and sanitary flow) and one for the hotel. The sheer size and scope of the project resulted in a large flow rate which proved challenging to fit given the proximity to a waterbody, low elevation and relatively high groundwater. Despite the challenges, our team was able to design a code-compliant solution that mitigates environmental impact by utilizing FujiClean Innovative and Alternative Onsite Wastewater Treatment Systems (I/A-OWTS).

This project is a testament to how progress can happen responsibly, blending modernity with nature. See below for the finished result!

This project is a testament to how progress can happen responsibly, blending modernity with nature. See below for the finished result!

Engineering Challenges

DAE faced a formidable task when dealing with such a high flow rate on a vast coastal site in Montauk. The hurdles were significant – a limited lot size of 1.2 acres, strict waterfront regulations, and the task of accommodating the required system sizes. Initially, the Population Density (calculated sanitary flow, Gallons Per Day, as of right based on lot area and groundwater management zone), figure stood at 707 which was far less than the desired use. However, due to a prior permitted use on the site, DAE was able to permit a grandfathered allowance of 3,600 GPD. To accommodate this tremendous flow rate, the team strategically designed three separate I/A septic systems, each tailored to the specific needs of the property: one for the kitchen, another for the restaurant bathrooms, and a third for the hotel. Groundwater testing played a crucial role, guiding the engineers to implement 4' deep leaching galleys as opposed to traditional leaching pools.. This accomplishment stands as a testament to DAE's expertise and commitment to overcoming complex design challenges, creating a harmonious balance between coastal preservation and modern infrastructure.