Structural Engineering Shop Drawings: Ensuring Precision and Quality in Luxury Home Builds

When building a high-end home, every detail counts—from the strength of the foundation to the precision of custom architectural features. Behind the scenes, structural engineering shop drawings play a pivotal role in bringing these unique designs to life. In any construction project, these drawings serve as the technical guide, translating the architectural vision into precise…

Frank Cuffaro

October 7, 2024

15 mins read

When building a high-end home, every detail counts—from the strength of the foundation to the precision of custom architectural features. Behind the scenes, structural engineering shop drawings play a pivotal role in bringing these unique designs to life. In any construction project, these drawings serve as the technical guide, translating the architectural vision into precise instructions for fabrication and construction.

In this article, we dive into how these drawings help streamline complex construction projects, prevent costly mistakes, and ensure that every element of your space is crafted with the utmost care and accuracy.

What are shop drawings?

Architectural and engineering drawings convey the design intent of a project, offering a vision of what the finished structure should look like. However, translating that vision into reality requires a deeper level of detail that accounts for both the unique conditions of the site and the specific design intent of the project —and that’s where shop drawings come in.

Shop drawings are specialized, highly detailed documents that serve as the bridge between design and construction. Unlike architectural and engineering drawings that present a broad design intent, shop drawings provide a step-by-step blueprint for the fabrication and installation of specific components. Contractors and fabricators rely on the contract documents provided, along with design intent drawings and specifications, to create these detailed plans. They incorporate critical information such as dimensions, materials, finishes, and connection details, tailored to actual field conditions.

These drawings go beyond standard plans by including multiple views—plan, section, elevation, and isometric perspectives—that offer a comprehensive understanding of how each element fits within the structure. For high-end residential projects, where custom features and intricate designs are often the norm, this level of detail ensures every component is accurately fabricated and installed, minimizing errors and aligning with the intended design.

By accounting for the unique conditions of each project site, shop drawings help ensure that what is built is not just in line with the architect’s vision, but also practical, safe, and achievable. This meticulous approach is key to delivering the exceptional quality and precision expected in luxury homes.

Construction Drawings vs Shop Drawings

In the realm of construction projects, both construction drawings and shop drawings are indispensable, yet they serve distinct purposes and cater to different stages of the construction process. Understanding these differences is crucial for architects, engineers, contractors, and suppliers to ensure seamless project execution.

Construction drawings, also known as architectural construction documents, are the blueprints prepared by architects to visualize the architectural elements of a project before actual construction begins. These drawings represent the overall design intent, encompassing architectural details of elements such as walls, windows, doors, siding and other structural components. They serve as a communication tool to convey the design vision to contractors, builders, and fabricators, ensuring everyone involved understands the project’s scope and aesthetic goals. Otherwise known as contract drawings, they provide the initial specifications that shop drawings build upon, ensuring that every detail is accounted for.

On the other hand, shop drawings are prepared by contractors and fabricators to illustrate the actual field executables. These detailed drawings provide comprehensive information about the manufacturing and installation of specific components during the construction phase. Shop drawings are essential for fabricators as they delve into the fabrication process, offering precise specifications and details necessary for creating and assembling the components. They bridge the gap between the design intent outlined in the construction drawings and the practical execution on the construction site.

While construction drawings set the stage by outlining the design intent, shop drawings take it a step further by providing the granular details required for fabrication and installation. This distinction ensures that every element of the project is meticulously planned and executed, maintaining the integrity of the design while addressing the practicalities of construction.

Types of Shop Drawings Used in Structural Engineering

Structural engineering shop drawings vary based on the materials and structural components used on the project. Below are a few examples of common types of shop drawings and what they typically include. Using popular CAD platforms is essential for generating shop drawings that are accurate and easily reviewed by all stakeholders.

Steel Shop Drawings

Steel shop drawings provide detailed information on all structural steel elements, including beams, columns, and connections. They specify the exact dimensions, hole placements, and connection details, such as welds or bolts, along with the locations of anchor bolts that secure the steel members to the foundation.

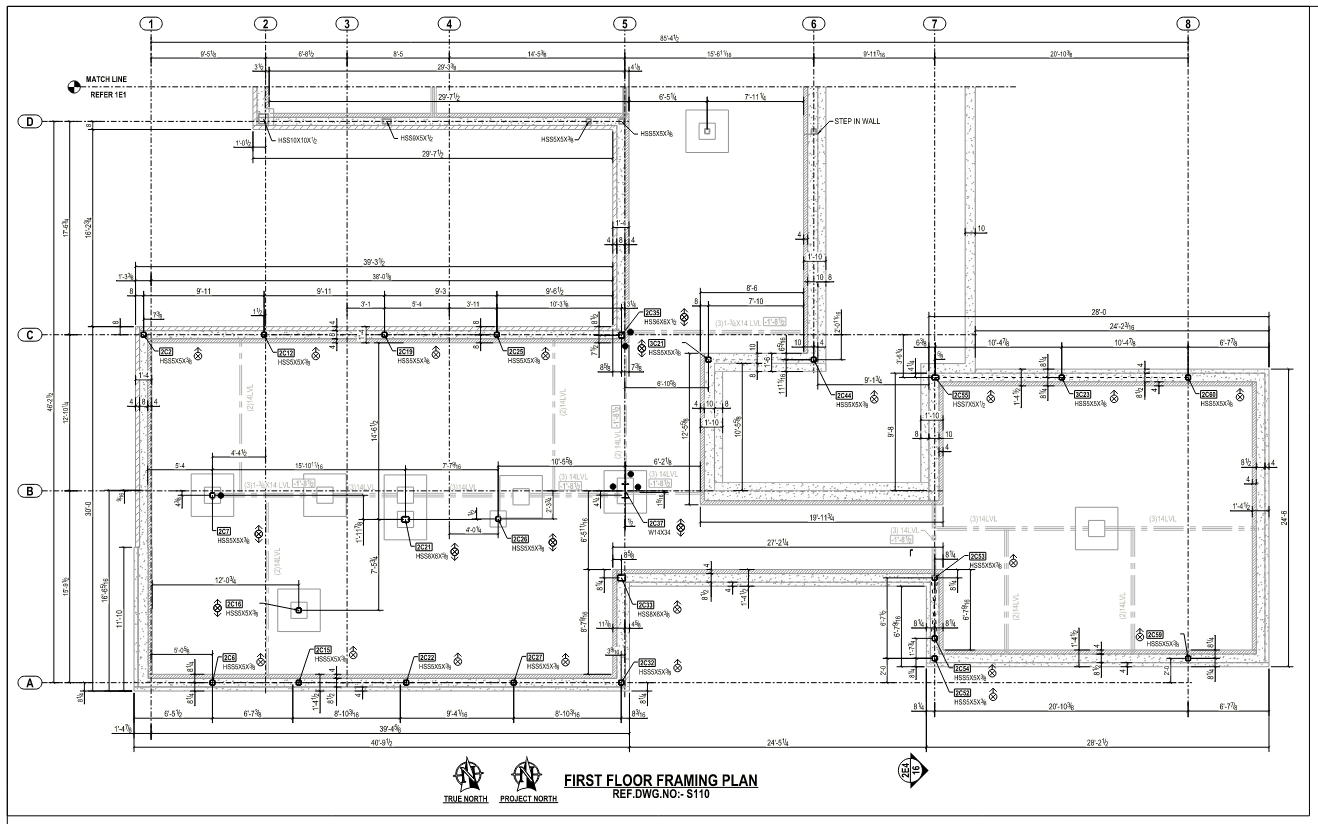

Example of a framing plan from a set of steel shop drawings.

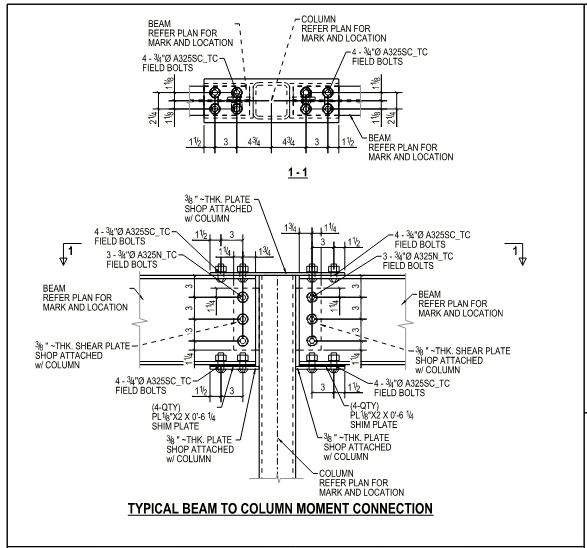

Example of a connection detail from the steel shop drawings set.

The steel shop drawings for this project detail the fabrication and installation requirements for each steel component, ensuring proper alignment and structural integrity.

Foundation Shop Drawings

Foundation shop drawings cover all aspects of the foundation system, including both concrete and reinforcement details. These include:

Rebar shop drawings: show the placement, size, and bending of reinforcing bars to ensure the foundation’s strength and stability.

Concrete shop drawings: include specific details and layouts for formwork and pouring sequences, ensuring that the foundation is built according to plan, maintaining structural integrity and safety.

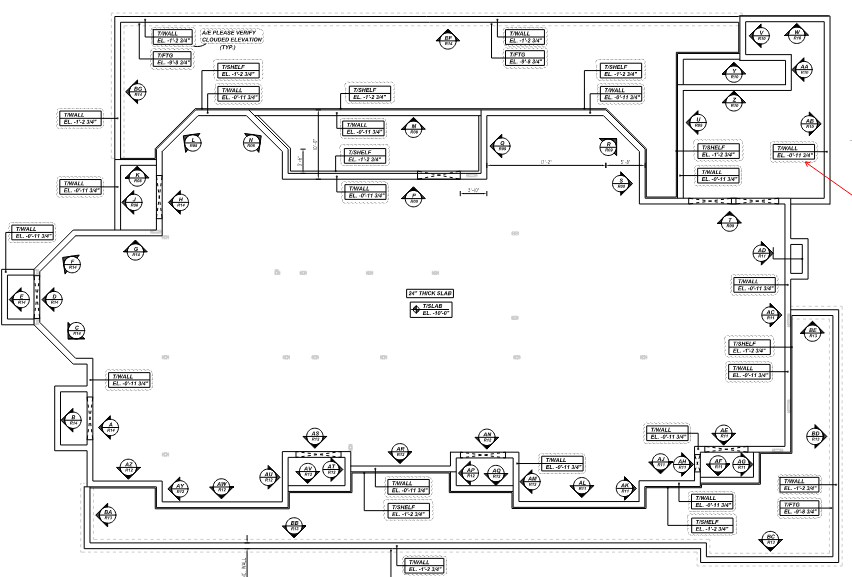

Example of a foundation plan from a set of foundation shop drawings.

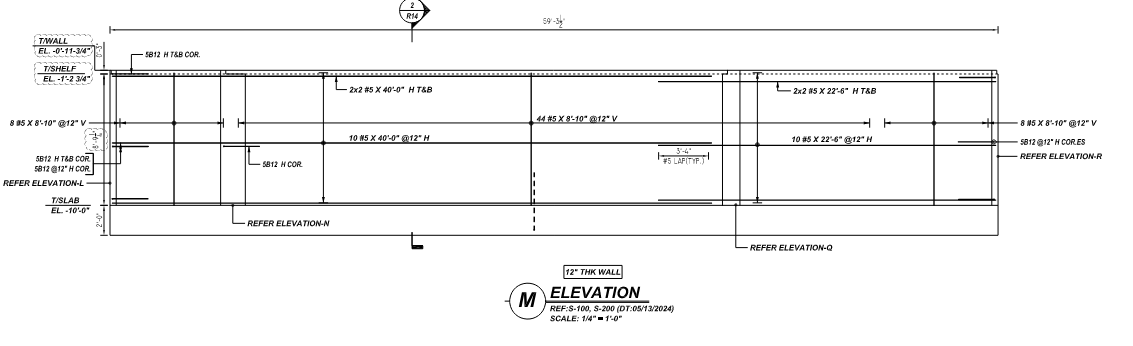

Example of a rebar/elevation detail from the foundation shop drawings set.

On this project, the foundation shop drawings were used to guide the precise placement of rebar and the layout of the concrete formwork, accommodating site-specific conditions to maintain structural performance and safety.

For accurate planning and estimation, tools like our Structural Materials Calculator can help determine the necessary materials and quantities, ensuring that every detail is accounted for from the start.

In addition to steel and foundation elements, MEP shop drawings can be crucial for ensuring that mechanical, electrical, and plumbing components are accurately integrated into the structure.

Information Included in Shop Drawings

Shop drawings are the backbone of the fabrication and installation process, providing a wealth of detailed information that ensures accuracy and efficiency. Here’s a closer look at the critical elements typically included in shop drawings:

Materials and Dimensions Required: Shop drawings specify the exact materials and dimensions needed for the fabrication, assembly, and installation of components. This includes everything from the type of steel or concrete to the precise measurements of each piece.

Explanations for Assembly, Installation, and Erection: Detailed instructions for the assembly, installation, and erection of components are provided, ensuring that every step of the process is clearly understood and followed.

Specifications and Details of the Project: Shop drawings include comprehensive specifications and details, such as weld types, connection methods, and material specifications. This information is crucial for ensuring that the components are fabricated and installed correctly.

Notes of Changes or Alterations from the Construction Documents: Any changes or deviations from the original construction documents are noted in the shop drawings. This ensures that all stakeholders are aware of and can account for these modifications.

Indication of Dimensions Needing Verification from the Jobsite: Certain dimensions may need to be verified on-site to ensure accuracy. Shop drawings indicate these dimensions, allowing for adjustments to be made as necessary.

Placement or Installation Information: Symbols, data, and instructions concerning the placement or installation of components are included. This may also involve a list of materials such as fasteners or adhesives required for the installation.

Samples: In some cases, a sample submittal may be required with the shop drawing, particularly for elements where color and texture selection of finishes are critical. This ensures that the final product meets the aesthetic and functional requirements of the project.

By incorporating these detailed elements, shop drawings provide a comprehensive guide for fabricators and installers, ensuring that every component is manufactured and assembled with precision. This meticulous approach not only enhances the quality of the final build but also minimizes errors and delays, contributing to a smoother and more efficient construction process.

Who’s Responsible for Shop Drawings?

The creation of shop drawings is a collaborative effort involving multiple parties, each with distinct responsibilities. The process begins after the architectural and engineering drawings are completed, and it relies on careful coordination to ensure that every detail of the design is accurately translated into actionable plans.

Step-by-Step: How Shop Drawings Are Created

Here’s a closer look at how this process unfolds:

1. Initial Coordination

The process starts with the general contractor (GC), who coordinates with the subcontractors and fabricators to identify all the elements that require shop drawings. This typically includes structural steel, concrete, rebar, and other custom components. The GC ensures that everyone understands the scope, timeline, and specific requirements for each set of shop drawings.

2. Preparation by Subcontractors or Fabricators

Typically, suppliers create shop drawings as part of the construction process. They use the architectural and engineering drawings as a foundation, incorporating additional details necessary for fabrication and installation. For instance, a steel fabricator will prepare detailed steel shop drawings indicating every beam, connection, and weld. Similarly, a concrete subcontractor will produce drawings for rebar placement, bending schedules, and formwork layouts.

3. Design Team Review

Once the shop drawings are prepared, they are submitted to the design team, which includes the structural engineer and architect. The design team reviews the drawings to ensure they align with the project’s design intent, structural integrity, and compliance with relevant codes and standards. The review process may involve several rounds of revisions to address any discrepancies or clarifications needed.

4. Approval and Compilation

After the design team’s review, the approval process begins, and the drawings are either approved or returned for modifications. The general contractor compiles the approved shop drawings from various trades, ensuring that all documents are consistent and coordinated with the overall project plans.

5. On-Site Execution

Once the shop drawings are approved, they serve as the primary guide for the on-site fabrication and installation of all structural components. The general contractor oversees this stage, ensuring that the construction team follows the approved drawings and coordinating any adjustments required due to unforeseen site conditions.

The structural engineer can also play a key role during this phase by visiting the site to verify that the work is being performed in accordance with the design intent and the shop drawings. The engineer helps resolve any issues that arise, answers RFIs, and provides technical guidance or modifications if unexpected conditions or conflicts occur. This collaborative approach ensures that the final build aligns with both the structural requirements and the project’s overall vision.

Industry Standards and Responsibilities

Standard contract documents, such as those provided by the American Institute of Architects (AIA), outline these responsibilities clearly. According to AIA guidelines on construction submittals, the subcontractor or fabricator is responsible for preparing accurate and complete shop drawings, while the design team’s role is to confirm that these drawings conform to the project’s design intent. The GC ensures that the entire process is managed efficiently, from preparation through to execution on-site.

Are Shop Drawings Really Necessary?

While shop drawings are not always strictly required for every project, they play a valuable role in achieving a high-quality build, especially in complex or high-end residential construction. There are a few factors to consider when deciding whether to invest in shop drawings.

Potential Drawbacks

Increased cost: Preparing shop drawings adds to the project’s overall cost, as they require detailed preparation by subcontractors or fabricators and thorough review by the design team.

Extended timeline: The process of creating, reviewing, and approving shop drawings can extend the project timeline, particularly if multiple revisions are needed.

Higher level of coordination: Shop drawings demand close collaboration between architects, subcontractors, contractors, and engineers to ensure that every detail aligns with the design intent and site conditions.

Despite the additional upfront time and cost, shop drawings are often recommended for high-end projects with custom features and complex details. The initial investment in creating these detailed plans can help avoid errors and miscommunications, ultimately saving both time and money.

Benefits of Shop Drawings

Reduce RFIs and unexpected delays: With detailed plans in place, there is less need for Requests for Information (RFIs) and fewer surprises during construction.

Ensure design intent is understood: Shop drawings help ensure that the contractor fully understands the design intent, resulting in a final product that meets the homeowner’s expectations.

Minimize change orders and additional work: By providing precise instructions, shop drawings reduce the likelihood of errors, minimizing the need for costly change orders or additional design work or rework. Regular coordination meetings

To maximize potential benefits, regular coordination meetings and the setting of a proper schedule for submitting shop drawings is crucial to ensure timely reviews and avoid project delays. For high-end residential projects, where precision and attention to detail are critical, shop drawings are a valuable tool in delivering a high-quality result and ensuring a smooth construction execution process.

When Are Shop Drawings Highly Recommended?

Shop drawings are particularly valuable in certain types of projects, where precision and coordination are key to achieving the desired end result. At DAE, we often recommend shop drawings in the following scenarios:

High-End Residential Projects with Custom Features

For luxury homes with unique architectural details, bespoke materials, or intricate design elements, shop drawings play a crucial role in maintaining the integrity of the design. These drawings provide precise, detailed instructions that translate complex architectural concepts into actionable plans for every contractor and fabricator. By clarifying how each custom feature — whether it’s a curved staircase, a custom steel beam, or a unique façade detail — should be built and installed, shop drawings help prevent costly mistakes and ensure that the finished product matches the client’s vision.

Projects Involving Custom Fabrication

When a project requires custom-fabricated components, such as structural steel or tailored millwork, shop drawings provide the exact measurements and specifications needed for fabrication. They enable the seamless integration of these components into the overall project by detailing every connection point and dimension. This minimizes the chances of errors during installation, saving time and avoiding potential delays caused by on-site adjustments.

Projects Requiring Tight Tolerances and Coordination

In projects with tight tolerances or where multiple trades must work together in confined spaces — such as coordinating plumbing, electrical, and HVAC systems — shop drawings offer a detailed roadmap that helps prevent conflicts. For example, beams, columns, and other structural components must be precisely aligned with ductwork, piping, and electrical conduits to avoid conflicts and ensure efficient use of space. By providing detailed layouts and connection points, shop drawings help map out every structural and MEP element in advance, reducing the risk of clashes and costly rework during construction. This level of coordination is particularly important in high-end residential projects, where even small misalignments can affect both aesthetics and functionality of the final space.

By leveraging shop drawings on these types of projects, we help our clients achieve their vision while minimizing risks, reducing the likelihood of change orders, and ensuring a smooth construction process from start to finish.

Building with Confidence and Precision: The Value of Shop Drawings in the Construction Process

For high-end residential projects, shop drawings go beyond basic documentation—they are a vital tool in turning sophisticated designs into structurally sound, beautifully executed spaces.

At Dilandro Andrews Engineering, we know that precise, well-coordinated shop drawings are essential to achieving the level of detail and quality our clients expect. Our engineering team meticulously reviews these drawings to identify potential conflicts, ensure alignment with the design intent, and coordinate seamlessly between all trades. By doing so, we help minimize costly errors, reduce delays, and ensure that every aspect of the structure aligns perfectly with both the architect’s vision and the realities of the construction site. When it comes to building luxury homes, this attention to detail is what makes the difference between a good project and an exceptional one.